Virtual Control Room & Igloo System for BP Whiting

TSC has supported BP to move the TSC Virtual Control Room (VCR) and Igloo system from its previous base at the BP training centre in Sunbury. The VCR is now to be re-commissioned at its new home in the Whiting refinery near Chicago.

BP made this move to aid local onsite training directly to operations staff.

The move saves having to transport staff to centralised hubs. Meaning fewer transport costs and overtime overheads, and more importantly a reduction in the environmental impact of training.

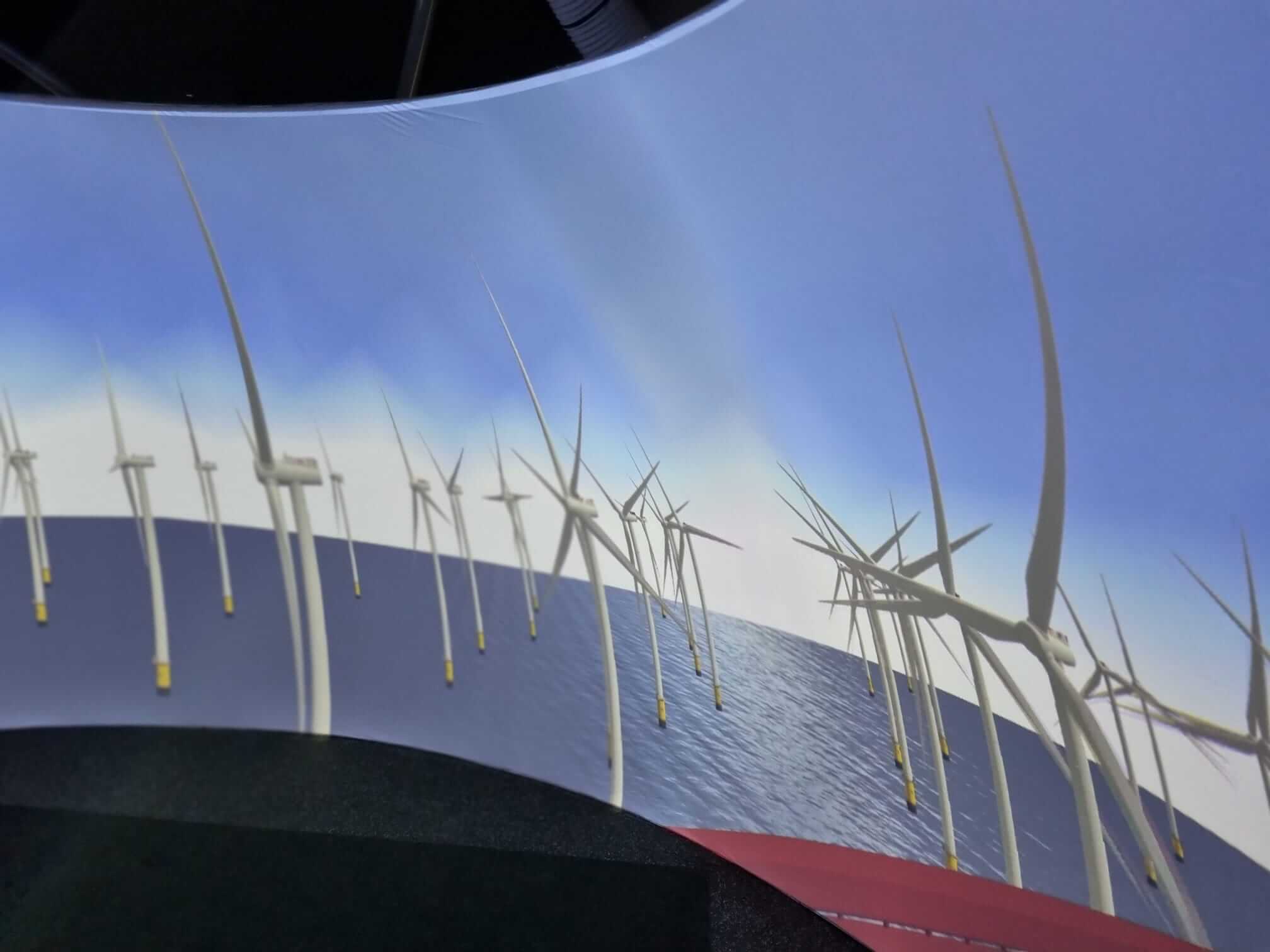

The Igloo display system allows users to Project virtual environments in a 360 arc around them in an immersive space. TSC’s Virtual Interactive Plant environment is projected within the Igloo giving a full-field operator experience. The system then connects to TSC’s mathematical model, any changes made in the virtual environment will give a realistic response. The virtual environment, is then wirelessly linked to the Virtual Control Room. Along with screens displaying the state of the process.

The system is installed with four of TSCs Interactive Virtual Plant Models which includes the Three Phase Separator, Centrifugal Compressor, Condensate Tank Farm, and the first installation of the new TSC Pipeline with Pigging model.

Also included in the Pipeline model is a full pumping system with a booster and the main pump system, with spare offline pumps. The fluid then subsequently passes through a full-metering system to the pipeline. The metering system includes a full-prover system to allow the calibrating of the flow meters. The pipeline does not only includes a pig launcher, but also two booster stations with the main pipeline bypass, and a Pig Receiver.

The virtual control system is supplied with an integrated Voice Over IP (VOIP) phone system. This allows important communication training to be carried out between the control room and field teams.

The system was demonstrated to several teams at the refinery ranging from instrumentation, maintenance, engineering, as well as operations. The system was extremely well-received by all teams and the trainees are excited to be involved with this industry-leading training technology.